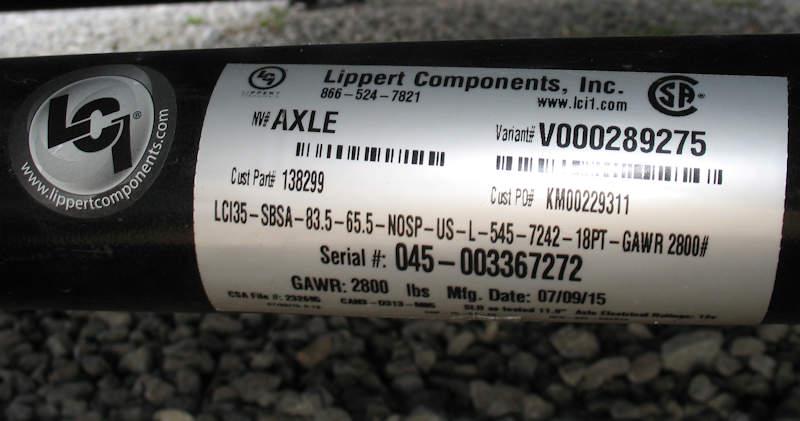

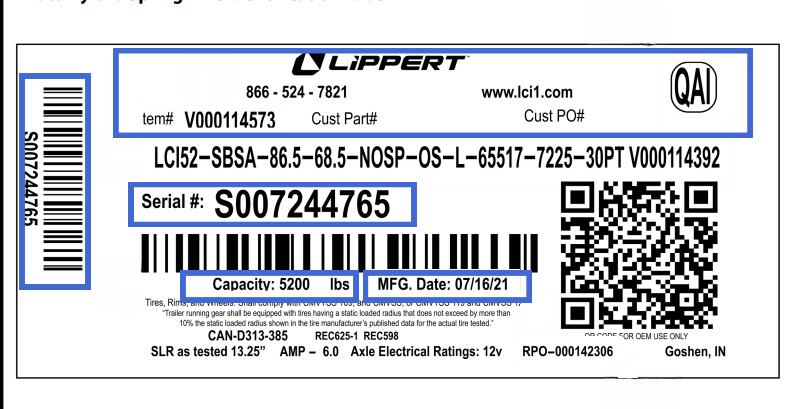

①Manufacturer’s Name and Logo

The manufacturer’s name and logo serve as the primary identification. This information establishes the credibility and origin of the axle. Knowing the manufacturer is crucial for warranty claims, recalls, and ensuring the use of quality components.

②Model or Part Number

The model or part number indicates the specific type or variant of the axle. This information is valuable when seeking replacement parts or when referring to the manufacturer for technical support. It ensures that the correct components are used for maintenance or repairs.

③Cust Po (Customer Purchase Order)

The Customer Purchase Order (Cust Po) is a reference number linked to the customer’s purchase transaction. This helps both the manufacturer and the customer trace and verify the purchase details, streamlining communication and facilitating after-sales services.

④Serial Number

The serial number is a unique identifier assigned to each axle by the manufacturer. This distinct code aids in tracking and differentiating individual units. It is essential for warranty purposes, recalls, and maintenance records.

⑤Mfg. Date (Manufacturing Date)

The manufacturing date specifies when the axle was produced. Knowing the manufacturing date is crucial for assessing the axle’s age, determining its potential wear and tear, and establishing maintenance schedules.

⑥Serial Number Barcode (Digits)

Many modern axle labels feature a barcode corresponding to the serial number. This barcode simplifies data entry and retrieval, making it easier for manufacturers and users to access information quickly and accurately.

⑦Capacity

This indicates the weight capacity of the axle, representing the maximum load it can safely carry.