A trailer jack is an essential component of safe towing. It’s a vertical device installed on the tongue of the trailer at the front. It can raise and lower the tongue of the trailer in front of it. You’d have to raise it by hand if you didn’t have a jack, which would be extremely difficult. As a result, you’ll want a trailer jack.

This article includes reviews of six of the most popular and finest American trailer jacks. Please scroll down and keep reading if you’re looking for it.

3. Weld-on Snap Ring Bracket Swivel Jacks

4. 12K Heavy Duty Square tube jacks

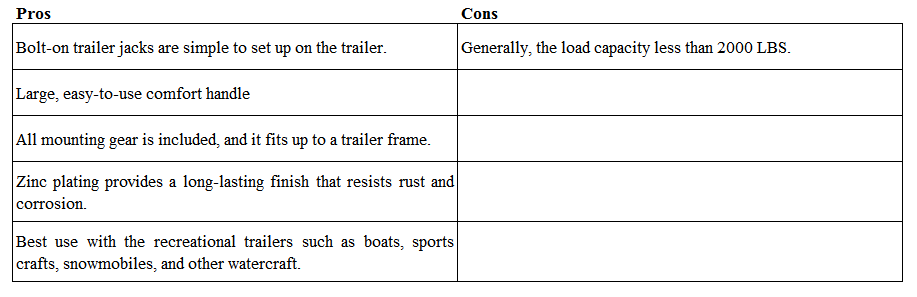

The marine swivel jack raises and drops the trailer and allows it to revolve thanks to its wheels. Boat trailers, utility trailers, enclosed trailers, and other trailers utilize it. The marine swivel jack is made to exact standards and requirements. It is made of the strongest materials and is meticulously crafted. The surface is coated with a water-resistant finish that can withstand a long-term salt spray test, ensuring that it will not rust if submerged in seawater for an extended period.

You should know the range of motion and maximum load of the marine rotary jack before using it. During usage, do not exceed this range, and do not overload. To avoid damage to the trailer’s front end or possibly jack failure.

The maritime swivel jack contains several spare components, which adds to the jack’s steady operation. The jack is likely to be useless once a portion is broken. As a result, you should inspect and lubricate the parts regularly.

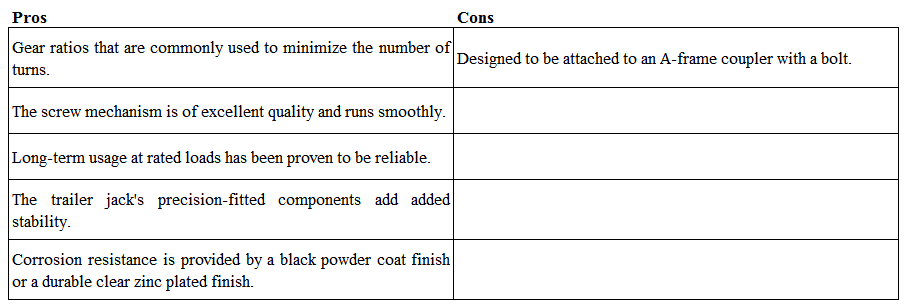

A-frame jacks are made particularly for trailers with A-frames. The front tongue of the trailer is attached to the A-frame trailer jack with three bolts. The A-Frame Trailer Jack has an established track record of delivering rated load reliability and dependable vertical and side load capacity. The trailer jack’s ergonomic shape makes it easy to operate and pleasant. The precision-assembled components of the trailer jack provide long-term stability.

These jacks may be used on a variety of trailers, each with its weight capacity. Utility trailers, such as landscaping trailers and enclosed trailers, are most often equipped with A-frame jacks.

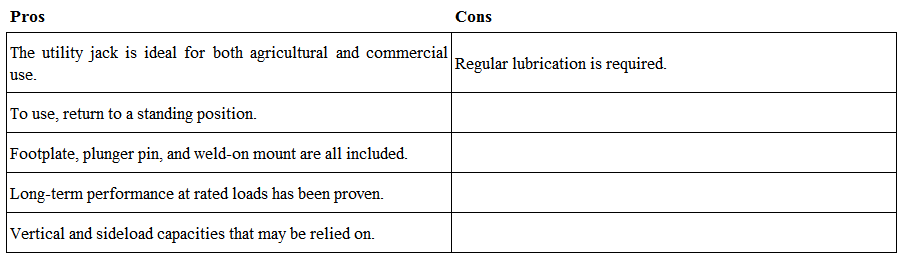

The swivel jack tube may “swivel” from a horizontal storage position to an active vertical position thanks to the weld-on snap ring bracket. This key characteristic may be used in a wide range of trailers. Boat trailers, utility trailers, cattle trailers, and recreational vehicle trailers are just a few examples.

This jack features a footplate soldered to the bottom for further stability. In difficult terrain, it provides robust protection for your trailer.

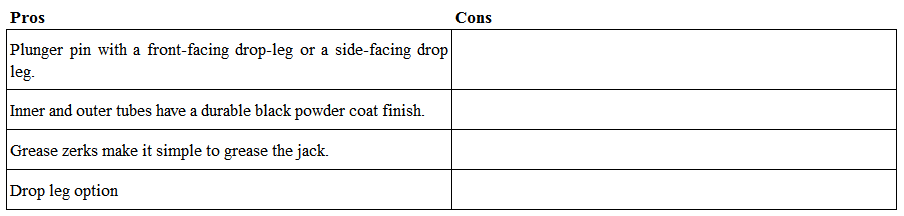

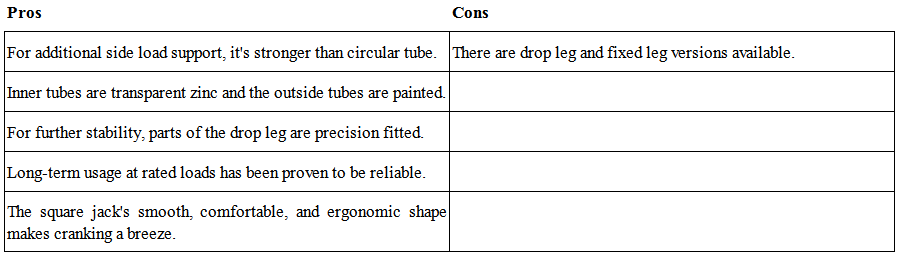

Heavy trailers may be lifted with the heavy-duty square tube jack. It has a spring return drop leg and a front-facing twin pin foot release.

Pro-Series heavy duty drops leg jack with spring return, rated at 12,000 lbs. Plunger pin with a front-facing drop leg. The crank is available for purchase separately.

Agriculture, construction, heavy utilities, and the horse/livestock trailer sectors utilize it to transport big loads of trailers.

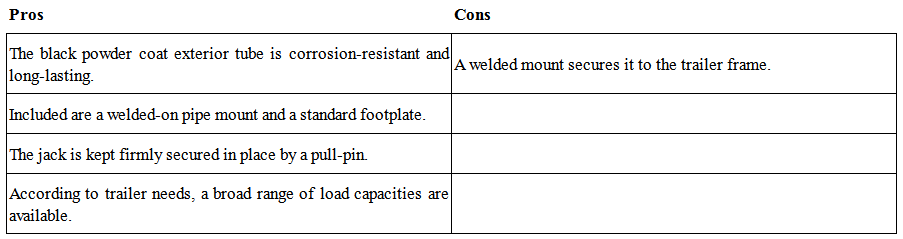

Pipe Mount Round Tube Jacks have a welded mount that attaches to the trailer frame that includes a raw steel pipe bracket that is ready to be welded. This trailer jack stand has a swivel bracket to guarantee enough clearance while pulling your trailer. The jack swings up and out of the way during towing, and a drawing pin secures it in position.

With the aid of these pipe mount swivel jacks, adjusting the height of your trailer has never been easier. The jack moves from the horizontal storage position to the active vertical lift position after welding to the neck of your trailer. When you use a mounting swivel trailer jack, connecting and disconnecting your trailer takes less time.

Trailer square jacks feature a small form and are built of square tubing. It makes them excellent jacks for situations where space is limited. Square jacks improve side load strength while preserving the cost-effectiveness of a low-capacity jack.

Corrosion resistance and service life are substantially improved using a black powder coat outer tube and a zinc-coated inner tube. The precision production method ensures that the product is dependable, smooth, and easy to spin for long-term usage. Gears and bearings last longer thanks to a convenient lubricating way.

Our trailer parts expert will answer your inquiries within 12 hours.

Tow-Max is a trusted supplier of trailer parts in China, known for its huge variety of products and one-stop services. We have been supplying customers from Australia, South America, the USA, and the Middle East. Our business partners are located in Sydney, Melbourne, Adelaide, Mexico City, Dubai, etc.

No.163-1, Shang yang Road, Dongqian Lake Industrial Zone, Ningbo, 315121, Zhejiang, China

+86-574-8786-2718

+86-574-8786-2717

sales(at)soaringtrailerparts.com

©Copyright 2020. Tow-Max. All rights reserved. Powered by MML.