We TOW-MAX are the industry’s leading supplier of trailer parts, with wide range products resourcing. We are also experienced in mixed container loading.

In following article, we will talk about how to earn money by optimal container space utilization.

Sea freight charge have continued to grow after the outbreak of the COVID. Shipping costs have increased by 4 to 10 times since early 2020. Many importers have been forced to postpone their procurement plans from China due to expensive transport expenses. However, instead of being worried about the cost of sourcing imports, our TOW-MAX customers have increased the frequency and volume of purchases.

Would you like to know the secret? In this article, we will reveal the secret to you.

Many importers have to adjust their business models as a result of the COVID outbreak, and others even went out of business due to broken capital chains. The COVID outbreak caused a reorganization of the industry and the loss of significant market shares. Isn’t it an exceptionally powerful competitive advantage if you can import at a cheaper cost than your competitors, resulting in a larger total profit? Do you want to know why our customers are making at least $2000 more per container than their competitors? Let us show you TOW-MAX’s amazing KDC profit enhancement method.

The unit weight of each container is certain. For example, in a 20-foot container, the conventional unit capacity is 17000 KG/28CBM, that is, 607KG/CBM; in a 40-foot flat container, the conventional unit capacity is 23000 KG/58CBM, that is, 396.6KG/CBM; in a 40-foot high container, the conventional unit capacity is 26000 KG / 68CBM, that is, 382.4KG/CBM. Therefore, as long as you know the procurement of goods density (total weight of goods/ total volume) and the choice of cabinet type, you can determine whether the cargo is heavy cargo or light cargo. If the density of the goods is greater than the container unit capacity, it is considered heavy cargo and vice versa for light cargo. The procurement of goods density closer to the unit capacity, the higher the utilization rate of the container.

However, many importers are usually based on product inventory for procurement. They rarely combined with the container loading situation, not to mention the calculation of the density of the purchased goods. Their suppliers have never popularized the relevant knowledge with them, and even though the volume of goods purchased did not reach the whole container, it did not remind them. This is very likely to lead to the following three situations.

When coupled with the lack of experience in many factories loading cabinets, improperly loading goods, etc. The container utilization rate is greatly reduced, and even the conventional 90% loading rate can not be reached. Combined with the current cost of shipping, the 10% of space is a real $2000 !

Our customers can make a full container purchase every time because we provide them with precise loading and placement solutions. Do you want to know how to achieve optimal container space utilization? Let us show you how the KDC profit enhancement method works!

1. Know the volume of the product in the container

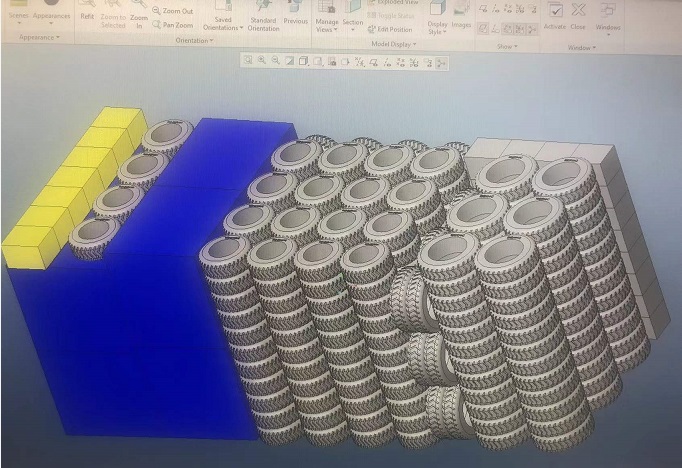

Different items require different types of loading containers. Tires and wheels, for example, are bulk packed into containers; other products are packed in cartons and placed straight into containers; while others are packed in wooden pallets and then loaded into containers. As a result, once we receive the customer’s shopping list, we will carefully calculate the size and weight of each product to improve container utilization. This process is called K ( Know the volume of the product in the container ).

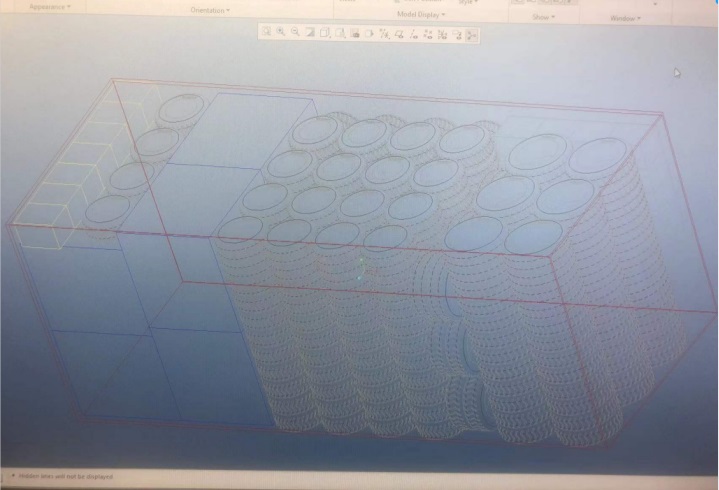

Following that, the data is counted and appealed. Then we’ll go over how to make a container loading chart. To make reasonable container loading planning, improve space utilization, and use CAD, SOLIDWORKS, and other drawing software to draw the container loading diagram, we will first calculate the actual loading space of the container, based on the customer’s order quantity and the loading size of different products, combined with our years of experience in container loading. Finally, a simulation of the procedure is run. This drawing process, we call D (Drawing the container loading plan).

Sea freight is so expensive in terms of the environment that 20 feet of container freight cost more than 10,000 dollars on several routes. The difference in freight rates between a 40 feet container and a 20 feet container, on the other hand, is only a few thousand dollars (usually under 5 thousand dollars). In this instance, we recommend that the customer combine light and heavy cargo in a suitable amount and prioritize the one-time purchase of 40 feet container cargo.

After confirming with the customer that extra items are required, assist the customer in calculating the number of these products that can be loaded based on the loading size. C is the abbreviation for the computation procedure (Calculation ).

To achieve the best utilization rate of the assembly space, we will load the cabinets according to the above-mentioned loading design, and then combine the loading employees’ years of practical experience to load the cabinets. We assist our clients in maximizing their earnings.

The impact of the COVID has wreaked havoc on every business. In such a difficult market, we must not only build new sales channels, but also maintain cost control, cut operational costs, and increase capital turnover efficiency, all of which will enable us to outperform our competition. To help you build your business, try our KDC profit increase strategy.

We TOW-MAX are the industry’s leading supplier of trailer parts, with extensive product resources and loading experience.

Our trailer parts expert will answer your inquiries within 12 hours.

Tow-Max is a trusted supplier of trailer parts in China, known for its huge variety of products and one-stop services. We have been supplying customers from Australia, South America, the USA, and the Middle East. Our business partners are located in Sydney, Melbourne, Adelaide, Mexico City, Dubai, etc.

No.163-1, Shang yang Road, Dongqian Lake Industrial Zone, Ningbo, 315121, Zhejiang, China

+86-574-8786-2718

+86-574-8786-2717

sales(at)soaringtrailerparts.com

©Copyright 2020. Tow-Max. All rights reserved. Powered by MML.