Complete Guide for Inspecting Trailer’s Leaf Spring

Trailer Leaf springs are a critical component of the trailer suspension, and as we all know, you cannot travel without them. However, many of us are unaware of our springs, and years might pass before considering them.

Typically, you think of your trailer leaf spring while sitting by the roadside or at a boat launch, waiting for the pricey tow trailer to arrive! And the most annoying part? It is avoidable; all that is required is understanding what to look for before departing on your journey.

A good trailer spring leads to a pleased trailer or boater. Any difficulties or hindrances to your movements can arise at any moment on Double Eye Springs, C-Hook (reverse curl) Springs, or Slipper Springs. These leaf springs are commonly found in boat trailers, utility trailers, and enclosed trailers, so be careful to inspect any trailers you may own to avoid future suspension troubles.

We encounter so many spring difficulties because trailer springs are not typically a portion of the trailer that wears or breaks readily unless the trailer is overloaded, severely corroded, or just old. As a result, springs are frequently overlooked during annual maintenance checks.

Trailer Leaf maintenance is important since damaged or failed leaf springs can result in trailer tire and axle damage and full suspension failure. To assist people in being secure on the road this year, we will discuss what to check for before hitting the road.

Trailer springs should be examined for cracks and regularly breaking to avoid spring failure. Cracks are most frequently found at the philister bolt and the eye of the bolt that links your spring to the hanger.

If you see a fracture or break in your spring windows, it is necessary to replace them. When a trailer spring breaks, serious damage to the trailer and boat can result, including full suspension failure, frame fractures, tire or hub damage, and trailer axle damage.

When examining your trailer springs, you should also look to see whether there is any daylight visible between the leaves of the spring. This is caused by the spring being fatigued over time due to the weight and use placed on it.

https://bit.ly/32rUgsZ

When springs become fatigued, they are unable to maintain the weight as well as they should. A spring that has been overworked may flatten out more quickly and may even break. Spring that is worn out is not safe springs!

Cracks in trailer springs can cause damage to the tire and trailer axle and the failure of the rear suspension and the complete trailer as a result of the damage. They are most commonly found around the eye that links the spring to the hanger and around the bolts.

Inspect these locations for any evidence of fracture or cracking that may have occurred. It is necessary to repair cracked or damaged suspension springs to restore their functionality and prevent serious damage to other suspension system components.

Corrosion is terrible for metals, and leaf springs are one of the trailer’s metallic components. They can rust when subjected to weather factors, chemicals, and corrosives. Rust steadily eats away at the metal, and over time, it develops structural problems.

https://bit.ly/3cALtXl

Additionally, rust reduces the load capacity and strength of the springs. They are susceptible to failure at any time, resulting in damage to the suspension system. Corroded springs are typically the result of age and poor care, and they should be replaced quickly before they break or fracture.

In addition, the amount of corrosion on your springs is something to keep an eye out for. The sort of rust that you should be concerned about is pieces of rust coming off the springs or big volumes of rust that would not be termed surface rust in the first place.

During the rusting process, the spring’s toughness and load capacity are reduced because the strong steel is being replaced with weak layered rust, weakening the spring’s overall strength.

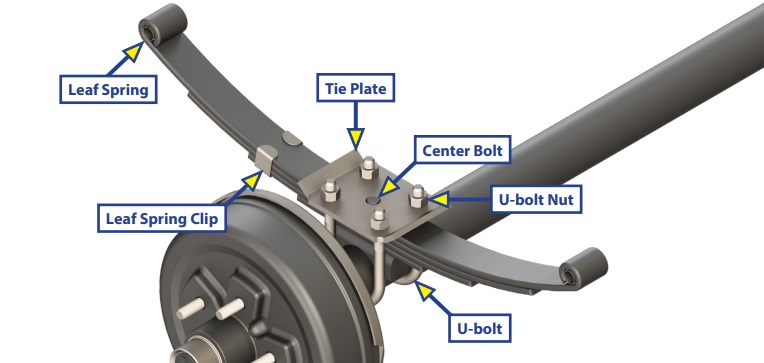

This year, avoid having a poor boating or fishing vacation because of a faulty and unsightly trailer spring installation. When you replace those old trailer springs, it is important not to fail to remember to get all of the necessary U bolt tieplate kits, spring bolts, shackle links, and spring hangers as well.

A smart approach to prevent your trailer from springs from decaying as rapidly is to use toilet ring wax and leave it to warm up in the sun before smearing it onto the trailer springs and letting it dry.

Because of this, the water can easily roll off the wax and not reach the spring as quickly. The surface rust on your trailer springs will accumulate over time, but you should never have cracks, substantial quantities of rust, or leaf separation on your trailer springs.

An old leaf spring should be removed and replaced if it has become badly rusted, fractures or breaks in its leaves, or starts to sag. A travel trailer that has been in use for 14 years may very well require new leaf springs.

https://bit.ly/2Z83pp0

The most important factors to consider when selecting replacement leaf springs are the axle capacity, the number of leaves, and the spring size. The weight rating of an axle is usually shown on a plate or label attached to the axle.

It is preferable to remove a spring from the suspension and measure the distance between the eyes of the spring. A badly worn spring can become elongated and measure up to 3/4-inch longer than it did when it was new. This is called spring elongation.

Gaps within the leaves of the springs are a poor indicator for the suspension system since they indicate a failure of the springs. Gaps are typically a symptom of springs that have become tired due to age or extra weight. It is recommended that you change your leaves if you can see through them throughout the day since they will break or flatten out after a short length of time.

If you wish to change your trailer leaf spring yourself, you would need to measure your trailer leaf spring, and you can follow these easy steps:

Adjust the current spring’s shape and type (dual eye, slipper-radius end, slipper-flat end, slipper-hook end, or slipper-open eye end), as well as its length and width.

Number the leaves; each spring steel layer is called a leaf.

Check the spring’s length while it is not loaded (jack up the vehicle by the frame); this is the spring’s free size.

For Double-eye and Open-eye leaf springs, gauge linearly from the middle of the front bushing to the middle of the rear bushing.

Measure linearly from the middle of the front bushing to the tip of the spring for, Radius-end leaf springs, Flat-end, and Hook-end.

The internal width of the bushing in the spring’s connecting eye must match the outside diameter of the spring hanger holes and fastening bolts that secure the spring.

https://bit.ly/3oNJzs6

Although 9/16” internal diameter bushings/bolts are the most frequent, some earlier trailers utilized 1/2” bushings/bolts.

While some leaf springs come with a 9/16” ID bushing in the closed eye, some come with a 1/2” ID bushing. Each spring should come with a description that includes the bushing size.

Additionally, spring capacity is specified per spring; so, a 4,000 lb. axle should be paired with two springs with a capacity of 2,000 lb. or greater.

One must never overlook the importance of a trailer leaf spring, and following the steps outlined in this article to inspect and probably replace your trailer leaf spring would help you out.

The leaf springs are crucial parts of the trailer’s suspension mechanism, and the equipment would be unable to function properly if they weren’t there to help.

Their function is to provide support for the trailer, absorb impact from potholes and bumps, and allow movement per the driver’s instructions.

Because they are susceptible to flaws and wear, leaf springs might have suspension troubles and perhaps fail. Learning how to examine these parts for wear and any symptoms of faults will help you avoid the difficulties and expenditures that come with a trailer that has broken down.

Leaf springs should always be replaced in pairs to ensure proper operation. If the lengths of the trailers are different, this might cause movement issues with the trailers.

Several trailer manufacturers say that the leaf springs are oiled regularly to ensure appropriate functioning and prevent premature wear and tear. Examine the manufacturer’s handbook before greasing the parts; in certain cases, the oil used on other trailer parts can be used on the springs if the manufacturer’s manual permits this.

Routine servicing of your trailer’s suspension unit can aid in the detection of these leaf spring issues before they have a chance to spread throughout the trailer. To ensure the long-term longevity of the trailer’s leaf springs, take it to an auto dealer for repairs and routine maintenance.

Our trailer parts expert will answer your inquiries within 12 hours.

Tow-Max is a trusted supplier of trailer parts in China, known for its huge variety of products and one-stop services. We have been supplying customers from Australia, South America, the USA, and the Middle East. Our business partners are located in Sydney, Melbourne, Adelaide, Mexico City, Dubai, etc.

No.163-1, Shang yang Road, Dongqian Lake Industrial Zone, Ningbo, 315121, Zhejiang, China

+86-574-8786-2718

+86-574-8786-2717

sales(at)soaringtrailerparts.com

©Copyright 2020. Tow-Max. All rights reserved. Powered by MML.