When looking for portable home trailers, selecting the appropriate weight and having the proper trailer axles for your car is critical. Four-wheel, two-wheel, and cross-over trailer axles and tires are the most often utilized trailer axles and wheels. The spacing between the axle and the wheel distinguishes these two types of trailer axles and wheels from one another. Four-wheel-drive wheels and axles have more significant space between the wheel and the axle than other kinds of wheels and axles. These are often the trailers used for smaller travel trailers or prefabricated houses that weigh less than a ton.

https://bit.ly/3pqWq5b

The decision to employ a technician to repair the axle on a trailer is popular among those who need the job done quickly and efficiently. When you have a little information, a few tools, and a good strategy in place, replacing a trailer axle is a chore that even the most novice do-it-yourselfer can do with relative ease.

When it comes to trailer axles, they are built to support a set amount of weight, which is determined by the amount of load that the trailer is rated to handle. Increasing the weight capacity of your trailer will need replacing the axles to ensure that they do not fail under the additional, more significant load that has been placed on them. Although not technically challenging, this requires a considerable amount of strenuous lifting. The procedure can be applied to other trailer models with minor terminology variations.

Axles in poor condition or that are neglected might be devastating. Axles are the core shafts that allow a wheel or gear to rotate.

An axle can be connected directly to the wheels to rotate. Additionally, an axle may be connected to the vehicle, whose wheels can spin around it.

Even in a standard vehicle, axles must operate correctly to move. Untended, built-up axles might result in your vehicle’s tires popping out unexpectedly while you’re traveling. Consider traveling at a high rate of speed on the freeway, and your axle breaks apart. The outcome might be catastrophic.

Step 1: Remove the trailer wheel

Step 2: Take off the bearing cap

Step 3: Detach the hub from the ring

Step 4: Disconnect the bearings from the machine

Step 5: Inspect the parts for signs of wear

Step 6: Clean and pack the bearings

Step 7: Begin the assembling process

If you are handling this by hand using a T-wrench or a ratchet, ensure that the trailer’s weight remains on the floor while unscrewing the nut. Raise the trailer while keeping the lug nuts free to remove the lug bolts and wheel. If you’re going to utilize an impact gun, make sure to elevate the trailer right away. If the lug bolt studs come off or twirl in the hub, hammer them out the rear of the intersection with a mallet and replace it with new studs to restore proper alignment. New studs may be inserted into the hub by pressing them in from the rear. They are prevented from spinning by splines.

https://bit.ly/3FvTMAk

The bearing cover, also known as the Bearing Buddy, can be removed while the wheel is off if it has been fitted. This can be performed by gently striking the edge of the bearing cover with a rubber hammer or using a channel lock. Pulling the cap away from the hub can also be accomplished using a screwdriver with a flat blade.

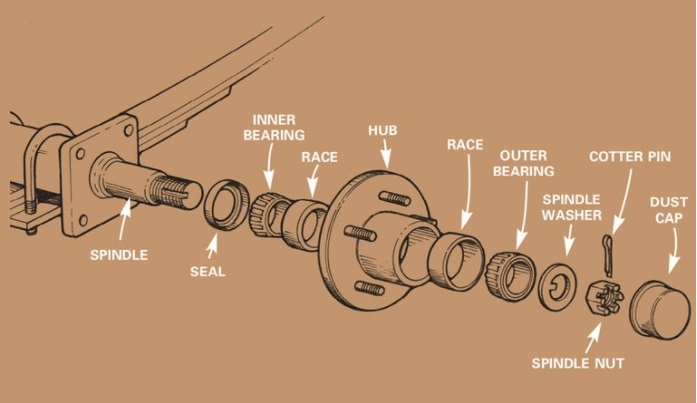

The cotter pin should be removed using needle-nose tweezers, and the bearing nut should be spun off as the next step. You should be able to unscrew this nut with your fingers, but if it’s too tight, you may need to use a big Crescent wrench or adapter. The hub can now be removed by yanking it straight off the shaft after being disconnected from the axle.

https://bit.ly/3ehbY54

The external wheel joint should come off from the wheel hub. To remove the inner bearing, pull away from the hub’s gasket and then lift the bearing out of the bearing housing. The seal will be destroyed during this procedure, and it will need to be replaced later. Because of the seal, grease is kept inside the hub, and pollutants are prevented from accessing the bearings. Remove any traces of dirty oil out from the hub so that the components may be examined. With a wire brush, clean the hub studs on your vehicle at this time as well.

Using a clean cloth, roll the bearings to remove excess grease and carefully check them for damage afterward. Slop between the rims and the cage is acceptable, but the rollers should be replaced if there is any roll friction or chatter when the rollers are spinning. If pits corrosion, or corrosion on the bearing or track, they must be changed as a complete set with the bearing or race. It is possible to remove races from the hub using a chisel and hammer and to replace them by delicately pounding them into the intersection with a workpiece once they have been carefully removed. To inspect for wear on the spindle, wipe it down with a shop towel and examine it closely; it should be completely smooth and shining. Because bearings wear out rapidly if the spindle is not smooth, it is necessary to replace it if the spindle is not smooth.

https://bit.ly/3EkDj0K

Using the heel of your hand, scoop a dollop of grease the size of a ping pong ball and rub it into the edges of the new bearing while spinning it so that any gaps between both the rims and cage are covered with fresh grease. While packing the other bearings, place each bearing on a clean cloth.

Start installing a seal into the hub by pushing it into the inner bearing once set in the hub. To install the seal, use a seal driver or socket with the same diameter as the seal’s outside edge. Make sure the seal is replaced with a new one that is the same size as the old one and is flush with the hub.

Place the hub onto the spindle with care, careful not to harm the new seal you just placed. Once the hub has been mounted to the spindle, the external bearing may be installed on the axle and locked into the hub position. Insert the washer and bolt as tightly as you can with your fingertips – do not use a tool to tighten it anymore. It is possible to overtighten this nut, putting too much strain on the bearing and causing it to overheat and fail. Check that the hub is rolling easily and with minimal drag by spinning it. The castle nut is designed with slots that allow a cotter key to be inserted through a hole in the tip of the spindle and into the nut. After the nut has been put through the spindle, twist the key to keep it in place.

The capping or bearing buddy should be installed by gently pounding it into the end of the axle with a hammer to tighten it. Place the wheel on the axle and use an anti-seize solution to coat the lug nut threads to prevent them from seizing. If necessary, gently seat all bolts against the wheel to center them, and then screw them in a cross pattern to approximately 80 pound-feet for most snowmobile trucks; see a dealer or trailer operator for torque standards. If the lug nuts are very rusted, they should be replaced.

Set the tire’s compressed air according to the specifications printed on the tire’s sidewall. If you do this maintenance in the autumn, make careful to reset the pressure before you pair up for your first trip this winter since the force will have changed since the last service session. Every time you tow, make it a practice to inspect the tires for damage. To lubricate greaseable bearings on your trailer, pour two or three shots of oil into the zerk, lower the jack, and the trailer’s axle is ready to go.

While it is crucial to keep all of the parts of your trailer in excellent operating order, the axles are of particular importance since they bear the brunt of the load. You may think of them as the central rods that link your trailer wheels to the trailer’s body. An issue with the axles of any wheeled vehicle might result in the vehicle being unable to move at all. It is possible that your essential goods will be lost or damaged when using a trailer.

One of the most important things to remember is to maintain your bearings oiled regularly when it comes to axle maintenance. Most axle difficulties your trailer may suffer are caused by a failure to perform this maintenance task correctly and consistently.

Our trailer parts expert will answer your inquiries within 12 hours.

Tow-Max is a trusted supplier of trailer parts in China, known for its huge variety of products and one-stop services. We have been supplying customers from Australia, South America, the USA, and the Middle East. Our business partners are located in Sydney, Melbourne, Adelaide, Mexico City, Dubai, etc.

No.163-1, Shang yang Road, Dongqian Lake Industrial Zone, Ningbo, 315121, Zhejiang, China

+86-574-8786-2718

+86-574-8786-2717

sales(at)soaringtrailerparts.com

©Copyright 2020. Tow-Max. All rights reserved. Powered by MML.