A trailer, even the custom-made ones, needs regular maintenance and care. You need to ensure that all its parts are in good working condition and well-maintained. However, among these parts, you must pay special attention to the axles.

Any wheeled vehicle with a problem with the axles will have difficulty moving. In turn, an unmoving trailer could mean a significant loss for your business, especially when the vehicle is loaded with cargo.

Axles serve as the central shafts connecting the trailer’s body to the wheels. Many of the problems with axles root from failing to keep them greased routinely.

With that said, here are the top 7 things you need to know about trailer axles and how to keep them in top shape.

https://bit.ly/3djXKj2

2. Single vs. Dual Trailer Axle

3. How to Determine Trailer Axle Rating?

4. How to Measure Trailer Axles?

5. How to Check Trailer Axle Alignment?

6. How to Repair or Correct a Bent Trailer Axle?

Trailer axles are typically categorized into two types – torsion axles and spring axles. These two types have similar jobs but differ in how they cushion and suspend the trailer load.

These axles do not rely on metal trailer springs. Instead, the torsion arms are secured to the inner core piece placed inside a square tube, containing a series of lengthy rubber cords.

The torsion axle also has a cross-section. Here, the torsion bars connect the inner square piece to each wheel, while the steel tubing comprising the outer square is attached to the frame.

When the trailer wheels go on an uneven or bumpy road, the rubber cords get compressed by the inner bar throughout the bearing surface.

Some of the plus points of using torsion trailer axles include the following:

The downside of this type is that it’s designed to undergo a total overhaul. So, you will need to cut off the axle to have a major repair done. On the other hand, repairs seldom happen due to the axle’s simple construction.

This type of trailer axle is more common and easily recognizable, especially to those who have been around motors for a long time. They are made from flat spring stock stacked according to the trailer’s load.

Unlike in a pickup truck where the spring is over the axle, the axle is suspended over the springs in trailers. As a result, the lower trailer gains more excellent load stability, and the trailer’s height decreases. This makes it easier to load and unload in the trailer.

Spring axles are easy to maintain and inexpensive – the top reasons they are among the popular choices in the suspension systems of a trailer. You can even have them shipped with pre-attached and ready-to-install curved spring plates.

They can also provide efficient applications, including most commercial trailers, dump trailers, and utility trailers.

Here are some of the benefits of using spring trailer axles:

You need to look under the trailer to know if it is a single axle or double axle. If it has one set of wheels, it is a single axle trailer, and it is a double or tandem axle trailer if it has two sets of wheels.

They are easier to maneuver since they are smaller than tandem axle trailers. This type is best suited for those without sufficient parking space to allow the trailer to wiggle.

https://amzn.to/32ZXHr7

It also consumes less fuel due to its size, making the trailer easier to tow with adjustable towing positions and lighter weight. A single trailer axle has fewer tires, meaning that you need to allot less for the cost of replacement and maintenance.

On the other hand, the small size of single axle trailers restricts their moving and storage abilities. Also, since only two tires handle the weight of the load, the tires can easily get worn out, especially if you often put heavy load and move a lot.

This type operates with a single axle connected to the wheel. It can be directly attached to the trailer bed using supporting hardware or clamps or attached via the springs.

Here are the advantages of using single axle trailers:

Here are the disadvantages of using single axle trailers:

Commonly referred to as a tandem axle trailer, this type uses two axles positioned near each other, ensuring the cargo’s weight load level distribution. Here, its two sets of axles are placed behind one another.

As a result, the trailer can move at high speeds with stability and carry more weight even when driven on highways due to the extra tires. This means you will have more room for the load you need to haul since the payload capacity is generally higher.

Tandem trailers are considered a good choice for expanding businesses since they can carry heavier loads. This will ensure that you can use the trailer for a long time, even as your business continues to grow.

https://amzn.to/3xQwEti

It may be more expensive upfront, but since you can use it for a longer time, you can consider the initial costs you paid for the trailer as an investment you will benefit from in the long run.

However, tandem axle trailers require level towing, which isn’t necessary with single axle trailers. It would be best to level the load all the time because not doing so might take a toll on the tires as one set of axles can suffer from wear and tear.

Here are the advantages of using tandem axle trailers:

Here are the disadvantages of using dual axle trailers:

The rated value of the load determines the rating of a trailer axle it can carry. This makes it easier for users to choose the more suitable trailer axle, depending on how they intend to use it. Different methods are being followed in assessing the trailer axle’s weighted grade.

Moreover, this rating pertains to the allowable weight you can place on each axle. So, the automaker of the trailer determines the weight limit and not any other governing bodies. This makes the manufacturer responsible for answering queries about the trailer axle weight rating.

The weights may not always be different, but the individual ratings depend on the rear and front axles. So, for example, if you are looking for a trailer capable of carrying 2550 pounds per axle, you have to look for a weight rating with one number listed, which is 2550 pounds.

You will often find the axle’s weight rating on the trailer’s primary identification sticker plate, located on the axle beam or a sticker plate. You will find the information valuable unless you have bought a second-hand trailer whose axles have already been replaced.

You can also get the rating by getting information about the axle diameter. Typically, a 6K or 7K weigh rating is given to an axle with a 3-inch diameter.

On the other hand, an 8K rating for an axle with a 3.5-inch diameter. There are also rare occasions when the 3.5-inch diameter is rated low at around 3500 pounds. However, the weight capacity of a trailer is more difficult to estimate. Trailer manufacturers differ in the safety margins they use in giving ratings to their trailers.

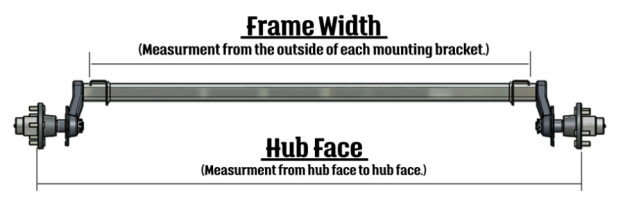

Measuring the trailer axles can come in handy when getting replacement parts. You need to know two vital measurements: the distance between the hub face or wheel hubs, tire centers, track width, and the measurement of the spring center.

If you get the measurements of the spring center right, you can quickly compute the measurement of the hub face. This will allow you to order a replacement for the damaged axle readily.

https: //bit.ly/3ddcTmf

Trailer axles usually use inches as a unit of measurement. Use the number you’ve gotten in buying a replacement axle.

The trailer’s axle may get misaligned or damaged due to many factors. You will notice the problem when the wheels get scrapped and dragged to the ground when moving. To prevent any mishaps from happening, it is best to check the trailer axle alignment regularly.

The first thing you need to do is to check the suspension. To do this, make sure to look for holes that have become bigger, causing things to move in the wrong direction.

To check the axle alignment, measure one of the wheels’ centers to the coupler’s back’s center. Then, measure the center of the other wheel. If the results are not the same or seem off, you can make the suspension loose so that you can straighten the axle.

You can repair a bent axle as long as you have welding skills by doing the following:

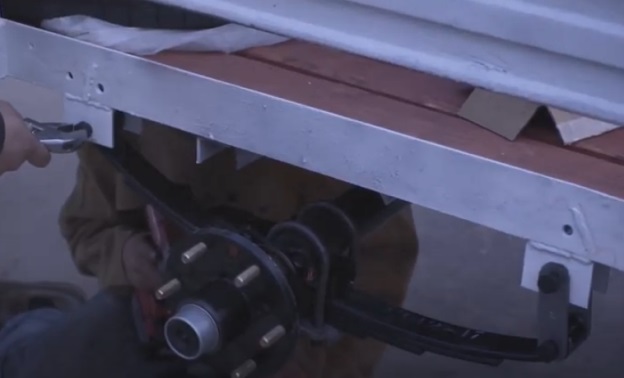

Follow these steps to install the axle on the trailer:

Having the basic knowledge about trailer axles, including measurement, maintenance, and replacement, will save you money in the long run. You only have to make sure that you have the tools and equipment to get things done.

Our trailer parts expert will answer your inquiries within 12 hours.

Tow-Max is a trusted supplier of trailer parts in China, known for its huge variety of products and one-stop services. We have been supplying customers from Australia, South America, the USA, and the Middle East. Our business partners are located in Sydney, Melbourne, Adelaide, Mexico City, Dubai, etc.

No.163-1, Shang yang Road, Dongqian Lake Industrial Zone, Ningbo, 315121, Zhejiang, China

+86-574-8786-2718

+86-574-8786-2717

sales(at)soaringtrailerparts.com

©Copyright 2020. Tow-Max. All rights reserved. Powered by MML.